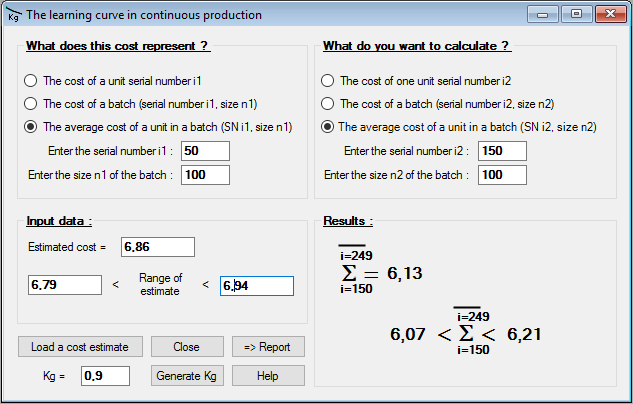

Effect of the learning curve in continuous production:

This module uses the Wright law, also called the Boeing law, for the effect of the learning curve in continuous production. This law of nature, with relation to costs, is valid in the following contexts for all kinds of repetitive operations (mainly manufacturing and preventive maintenance) :

- Unchanged product (no substantial modifications during the course of manufacture),

- Fixed workstations and fixed tooling for manufacture,

- Permanent operators or always those having similar qualifications.

Industrial surveys have shown that :

- The required time for the execution of a task decreases each time that the operator passes from one item to the next one thanks to the experience he is acquiring,

- A saving in time always exists but it diminishes each time that the operator passes to the next item,

- The time saving is different depending on the nature of the work carried out.

Nonetheless, a generic constant coefficient, called a global learning coefficient (kg) can be identified. Its numerical value is a function of the type of product and the manufacturing process. There is an infinity of coefficient of learning curves corresponding to a family whose numerical value can be calculated by the CCOStat generators, when they analyse the parameters provided by the user to define the product/process.

The constant coefficient of learning is that of C(2i) = kg x C(i) where “C” is the cost (or the price) of the manufactured item and “i” its sequence number, that is to say its sequential number of completion from the beginning of the activity. This amounts saying that the production costs are multiplied by kg when the sequence number in the production doubles. A module for calculating the Kg is also available.